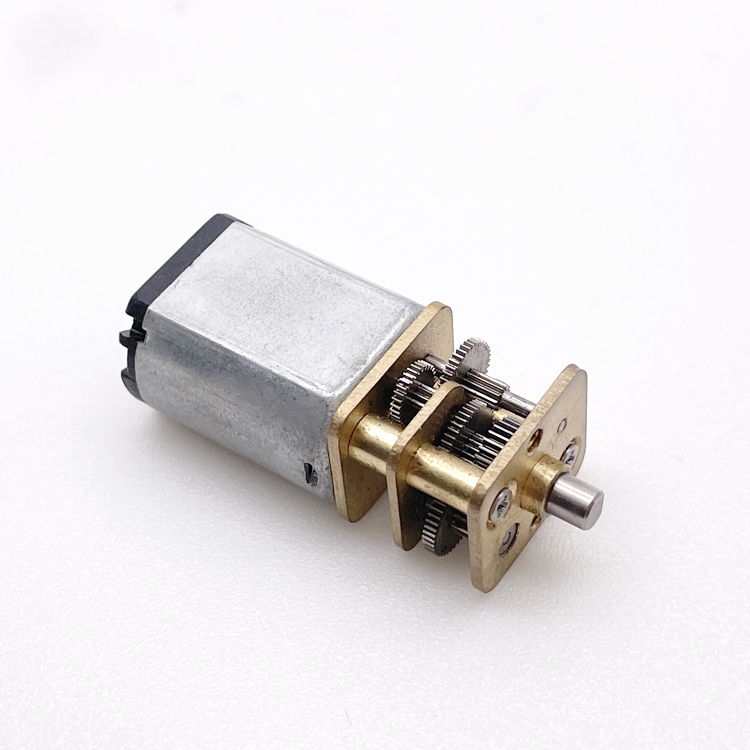

GM12-N20VA 12mm Mirco High Torque DC Gear Motor

| Protect Feature | Drip-proof |

| Speed(RPM) | 1~1200rpm |

| Continuous Current(A) | 30mA~60mA |

| Efficiency | IE 2 |

| Application | Home Applicance |

| Keywords | High Torque Gear Motor |

| Motor type | Brush PMDC Motor |

| Feature | High Efficiency |

| Rated Speed | 10rpm-1200rpm |

| Load Capacity | 0.5N |

| Input Voltage | DC 2.4V-12V |

| Power | 0.5W Max (Can Customize) |

| Weight | 10g |

| Noise | Low Noise Level |

Gearboxes, also referred to as gearheads or gear reducers, are enclosed systems consisting of a series of integrated gears within a housing unit. Gearboxes are designed to transmit mechanical energy to operate and alter the torque and speed of a driving device, such as an electric motor.

How does a gearbox work?

Inside a gearbox, there is one of several different types of gears that can be found - these include bevel gears, worm gears, helical gears, spur gears, and planetary gears. These gears are mounted on to shafts and rotate on rolling element bearings.

What type of gearboxes are there?

The most common types of gearboxes are spur and planetary.

Spur gearboxes have straight teeth and are mounted on parallel shafts. Spur gearboxes offer a high power transmission efficiency, a constant velocity ratio and have no slip.

Planetary gearboxes have the input shaft and output shaft aligned. They are particularly suited to high torque and low-speed applications.

How is the gear ratio defined?

The gear ratio is defined through the number of turns the output shaft will makes when the input shaft is turned once. When the gear ratio is 1:1, the torque and speed are the same. If the ratio is increased to 1:4, the torque is reduced and the maximum speed is significantly increased. If this is reversed to a ratio of 4:1, then the speed is reduced and the torque is increased.

What are gearboxes used for?

Gearboxes are used in various applications depending on the type and gear ratio. This includes machine tools, conveyor systems and elevators, as well as industrial equipment and mining industry applications. Right angle gearboxes can be utilized in rotary tables.

1.Small size dc gear motor with low speed and big torque

2.12mm gear motor provide 0.1Nm torque and more reliable

3.Suitable to small diameter, low noise and big toque application

4.Dc Gear motors can match encoder, 3ppr

5.Reduction Ratio: 3、5、10、20、30、50、63、100、150、210、250、298、380、1000

1.Wide range of DC gear motors

Our designs and manufactures a wide range of high-quality, and cost-effective, Ø10 -Ø60 mm DC motors in a range of technologies. All types can be highly customised for a wide range of applications.

2.Three main DC Gear motor technologies

Our three main DC gear motor solutions use iron core, coreless and brushless technologies with two gearboxes, spur and planetary, in a variety of materials.

3.Customised for your application

Your application is unique so we expect you to need some custom features or specific performance. Work with our application engineers to design the perfect solution.