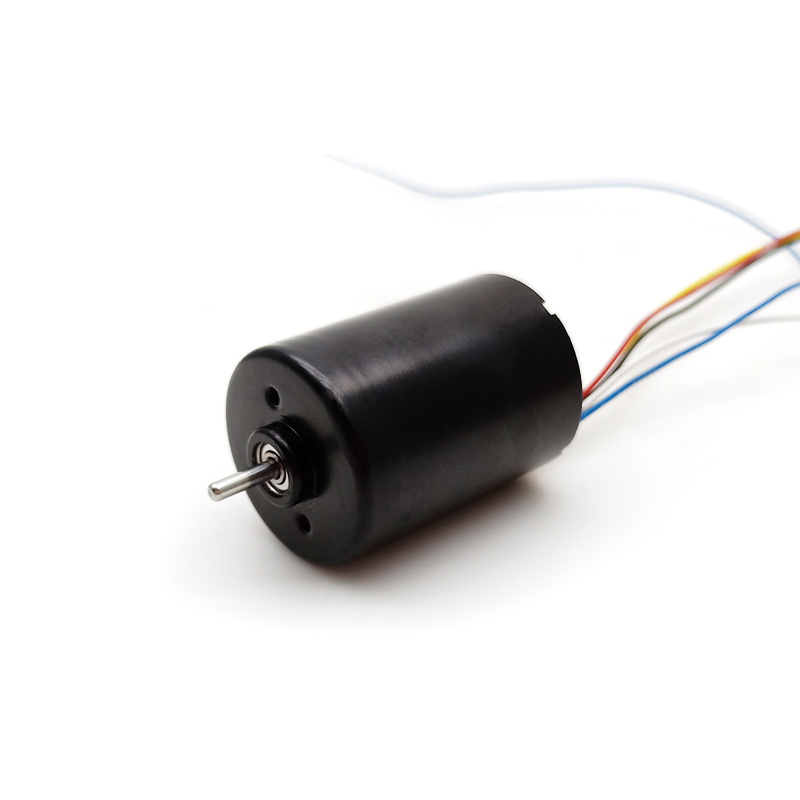

TEC3040 12V 24V High Torque Long Life Silent Motor BLDC Brushless Motor

1. Brushless motors have a longer life span because they use an electronic commutator rather than a mechanical commutator. There is no commutator or brush friction. The life of the brush motor is several times longer.

2. Little interference: Because the brushless motor eliminates the brush and does not use an electric spark, the interference to other electrical devices is reduced.

3. Minimal noise: Due to the DC brushless motor's basic structure, spare and accessory parts can be precisely mounted. The running is relatively smooth, with a noise level of less than 50 decibels.

4. Brushless motors have a high rotation rate since there is no brush and commutator friction. The rotation rate can be increased.

precision drives in medical equipment, industrial automation fields.

Options:Lead wires length,Shaft length,Special coils,Gearheads, Bearing type ,Hall sensor,Encoder,Driver

The brushless dc motor (BLDC) utilizes electronic commutation instead of mechanical commutation which overcomes the weaknesses of contact-type (brush) commutation, while providing excellent reliability and extremely long lifetime. Attributes of the motor’s excellent performance include: high reliability, high rotational speed, excellent size to power ratio, high short-term overload capability, low EMI, good speed regulation .

A common product, brushless dc motors (BLDC motors) have the qualities of low interference, low noise, and long life. A high-precision planetary gearbox is used in combination with it due to its excellent performance to significantly increase the torque of the motor and decrease its speed, making it suitable for a variety of application fields.