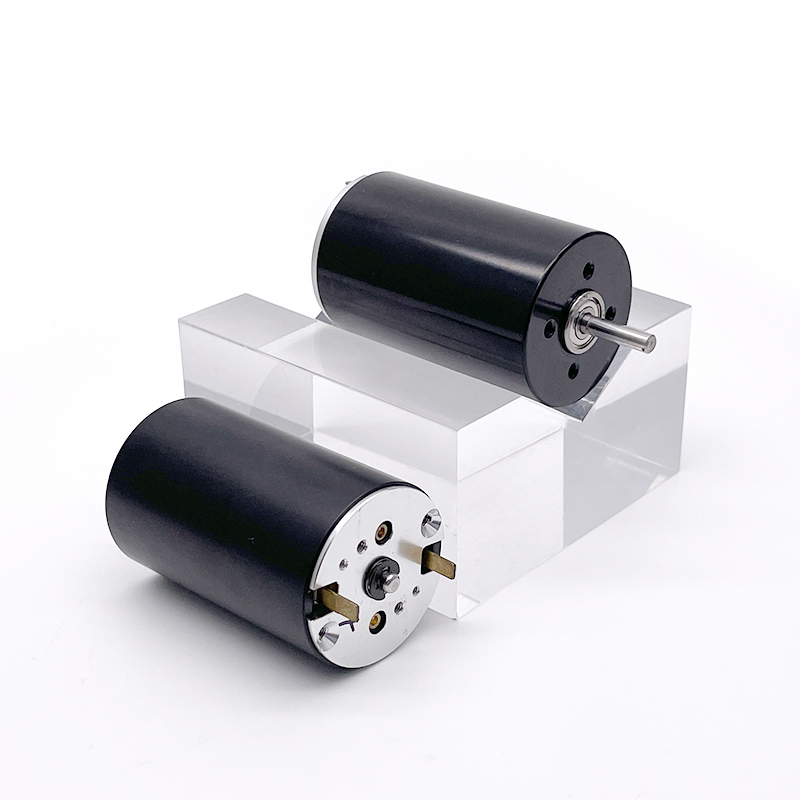

TDC2230 2230 Strong Magnetic DC Coreless Brushed Motor

Bi-direction

Metal end cover

Permanent Magnet

Brushed DC Motor

Carbon Steel Shaft

RoHS Compliant

1. A follow-up system that requires fast response. Such as the rapid adjustment of the flight direction of the missile, the follow-up control of the high-magnification optical drive, the fast automatic focus, the highly sensitive recording and testing equipment, the industrial robot, the bionic prosthesis, etc., the hollow cup motor can well meet its technical requirements.

2. Products that require smooth and long-lasting dragging of the drive components. Such as all kinds of portable instruments and meters, personal portable equipment, field operation equipment, electric vehicles, etc., with the same set of power supply, the power supply time can be extended by more than double.

3. All kinds of aircraft, including aviation, aerospace, model aircraft, etc. Utilizing the advantages of light weight, small size and low energy consumption of the hollow cup motor, the weight of the aircraft can be reduced to the greatest extent.

4. All kinds of household electrical appliances and industrial products. Using the hollow cup motor as the actuator can improve the product grade and provide superior performance.

5. Taking advantage of its high energy conversion efficiency, it can also be used as a generator; taking advantage of its linear operation characteristics, it can also be used as a tachogenerator; coupled with a reducer, it can also be used as a torque motor.

TDC series DC coreless brush motor provides Ø16mm~Ø40mm wide diameter and body length specifications, using the hollow rotor design scheme, with high acceleration, low moment of inertia, no groove effect, no iron loss, small and lightweight, very suitable for frequent start and stop, comfort and convenience requirements of hand-held applications. Each series offers a number of rated voltage versions based on customer requirements to give gear box, encoder, high and low speed, and other application environment customization possibilities.

Using precious metal brushes, high performance Nd-Fe-B magnet, tiny gauge high strength enamelled winding wire, the motor is a compact, light weight precision product. This high efficiency motor has a low starting voltage and a low power consumption.