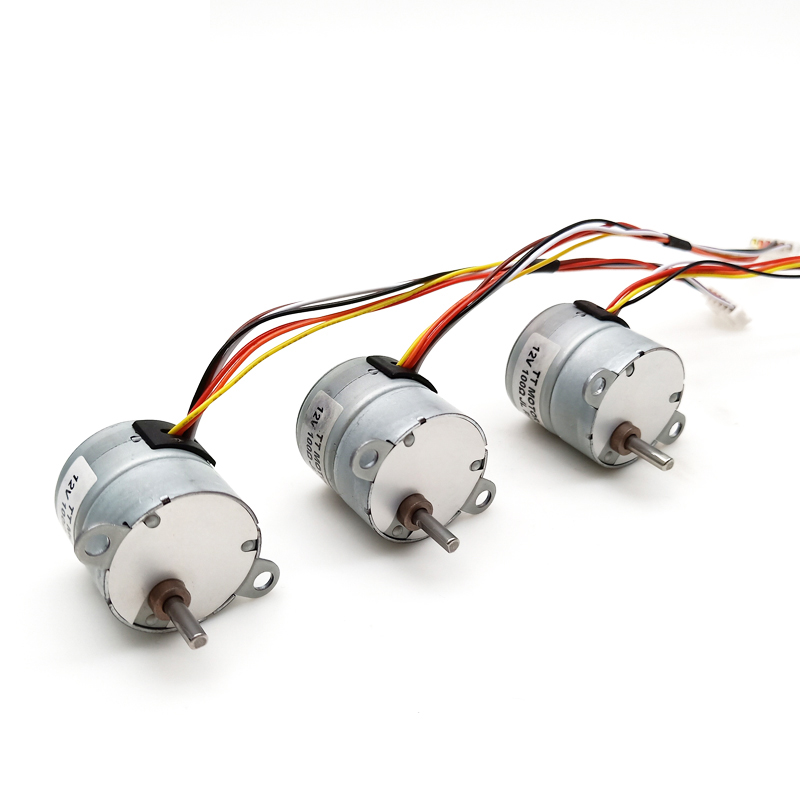

GMP06-06BY TT MOTOR 6mm High Torque Geared Micro DC Small Stepper Motor With Planetary Gearbox

High Precision: Precision machining technology is used to ensure smooth operation of the motor and high positioning accuracy.

High Reliability: High-quality materials are selected to improve product durability and anti-interference ability.

Low Noise: Optimize the motor structure, reduce operating noise, and create a comfortable use environment.

Environmental Protection: Efficient energy conversion, reduced energy consumption, in line with the concept of green environmental protection.

Easy to Install: Small and light, easy to install, and save space.

High Step Angle Accuracy: High-precision gears are used to ensure step angle accuracy and meet the needs of various application scenarios.

Good Compatibility: Can be used with various controllers and drivers, with strong compatibility.

Powerful Driving Ability: Large output torque, can drive large loads.

High Protection Level: Sealed design, dustproof, adaptable to various harsh environments.

Wide Range of Reduction Ratio Selection: Provide a variety of reduction ratios to meet the needs of different scenarios.

Automation Euipment: 3D printers, engraving machines, laser cutting machines, etc.

Robots: Used for robot joint drives, walking drives, etc.

CNC Machine Tools: Used for precision positioning, feed drives, etc.

Medical Equipment: Rehabilitation robots, operating tables, etc.

Office Equipment: Printers, copiers, etc.

Smart Homes: Electric curtains, smart locks, etc.