-

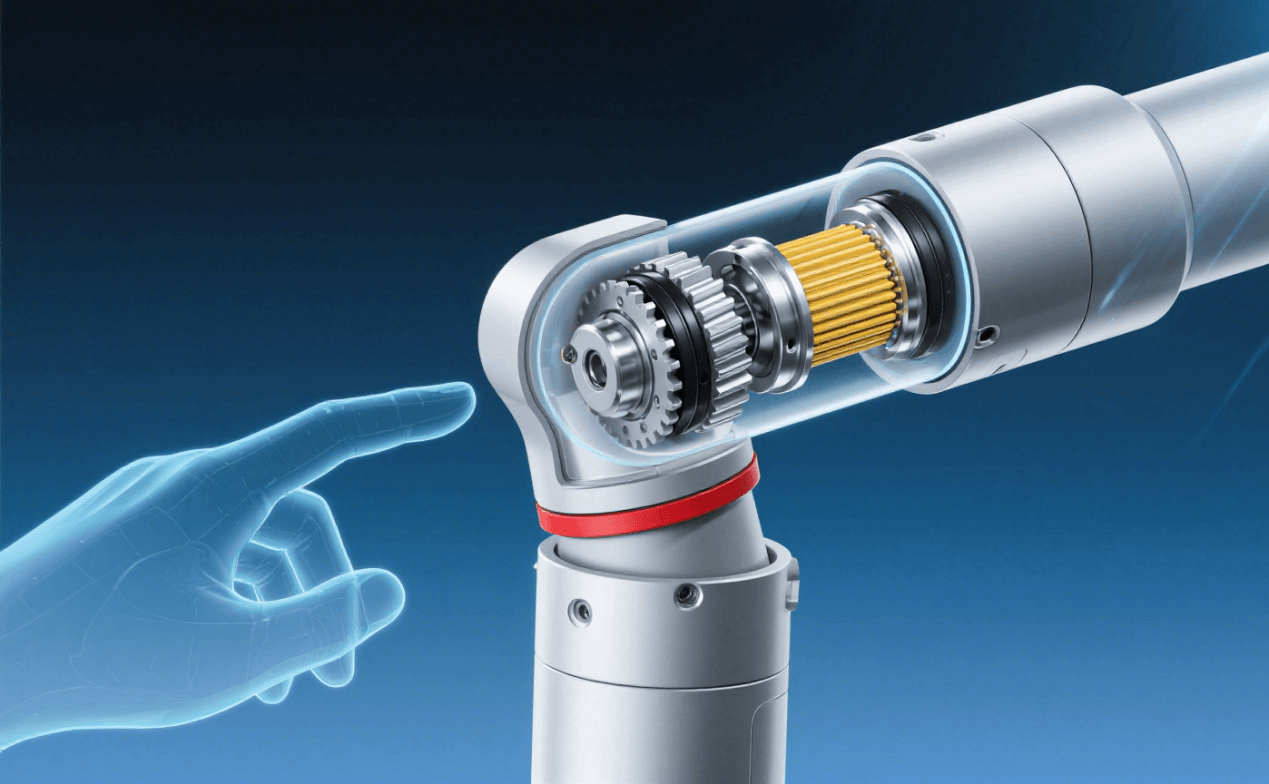

How TT MOTOR’s precision motors empower machines with a more human-like experience

We are entering a new era of human-robot collaboration. Robots are no longer confined to safe cages; they are entering our living spaces and interacting closely with us. Whether it’s the gentle touch of collaborative robots, the support provided by rehabilitation exoskeletons, or the smooth...Read more -

The Micromotor Green Revolution: How TT MOTOR Supports Sustainable Development Goals with Efficient Technology

As the world strives for carbon neutrality and sustainable development, every decision a company makes is crucial. While you’re focused on developing more energy-efficient electric vehicles and more efficient solar systems, have you ever considered the microscopic world hidden within these ...Read more -

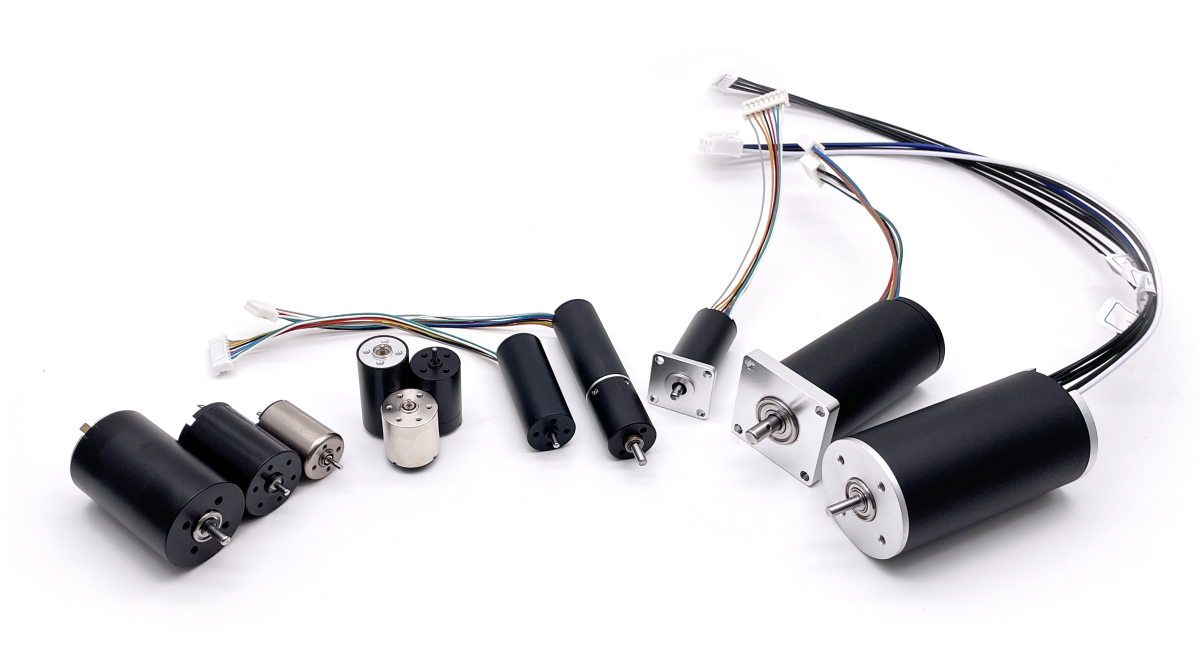

TT MOTOR’s Full Range of Coreless Motors, High-Performance Customized Solutions

In the intelligent era, innovative products are increasingly demanding core power units: smaller size, higher power density, more precise control, and more reliable durability. Whether in collaborative robots, precision medical devices, high-end automation equipment, or aerospace, they all requir...Read more -

10mm Brushed Coreless Planetary Gear Motor, Designed for High-Performance Applications

In the field of precision drives, every tiny component determines the efficiency and reliability of the entire system. Whether in medical devices, robotic joints, precision instruments, or aerospace equipment, the requirements for micro DC motors, the core power components, are extremely stringen...Read more -

TTMOTOR:Providing Flexible and Efficient Solutions for Robotic Electric Gripper Drives

Amid the rapid advancement of robotics technology, electric grippers, as key actuators for interacting with the outside world, have a significant impact on the competitiveness of the entire robotic system. The motor, the core power component that drives the gripper, is crucial for its operational...Read more -

Fully self-developed integrated Brushless Planetary Gear Motor

With over 20 years of experience in the integrated drive and control motor field, we leverage our comprehensive R&D capabilities and global manufacturing footprint to offer a comprehensive range of brushless motors, brushless geared motors, brushless planetary geared motors, and coreless moto...Read more -

Leading the Industrial Future: A Fully In-House Integrated Brushless Planetary Gear Motor with Encoder

In the manufacturing fields of industrial automation and precision drive control, the reliability of the core power unit of a brushless gear motor directly determines the equipment lifecycle. Leveraging over 20 years of experience in brushless gear motor R&D, we integrate Swiss precision tech...Read more -

GMP12-TBC1220: The Ideal Choice for Driving Robotic Electric Grippers

In today’s micro-automated precision control landscape, robotic electric grippers have become essential intelligent control devices in numerous applications, including precision industrial production, precision manufacturing, and logistics warehousing. They perform thousands of precise oper...Read more -

Micromotor market size to exceed US$81.37 billion by 2025

According to SNS Insider, “The micromotor market was valued at US$ 43.3 billion in 2023 and is expected to reach US$ 81.37 billion by 2032, growing at a CAGR of 7.30% during the forecast period 2024-2032.” The rate of micromotor adoption in aut...Read more -

Application of planetary gear motors

Planetary gear motors are widely used in various industries. Here are some specific examples: 1. Automated assembly lines: In automated assembly lines, planetary gear motors are often used to drive precisely positioned sliders, rotating parts, etc. Due to their high precision and high torque char...Read more -

Advantages of Planetary Gear Motors

The planetary gear motor is a transmission device that integrates the motor with the planetary gear reducer. Its advantages are mainly reflected in the following aspects: 1. High transmission efficiency: The planetary gear motor adopts the principle of planetary gear transmission and has high tra...Read more -

What are the special requirements for the application of DC motors in industrial robots?

The application of DC motors in industrial robots needs to meet some special requirements to ensure that the robot can perform tasks efficiently, accurately and reliably. These special requirements include: 1. High torque and low inertia: When industrial robots perform delicate operations, they ...Read more