productclassification

aboutus

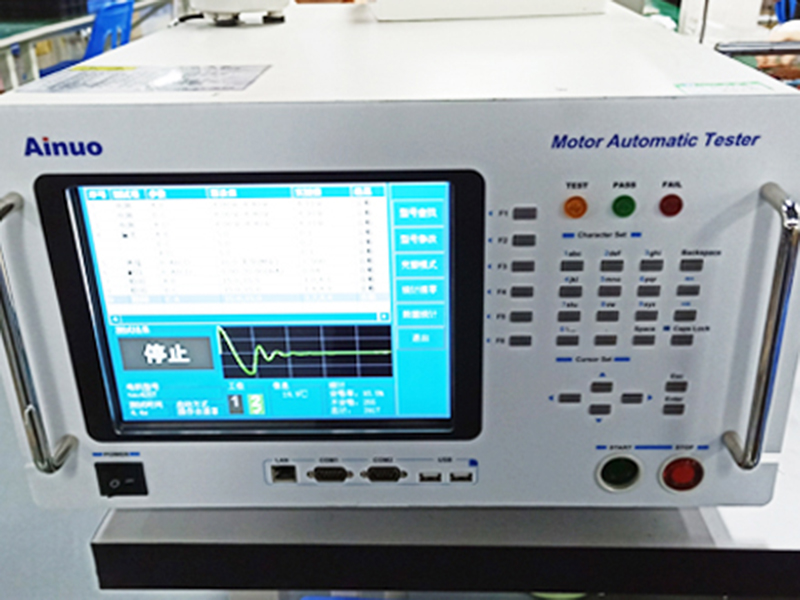

We have a strong R & D team and manufacturing capabilities, with professional brush motor and brushless motor production lines, through years of technology accumulation and product customization of key customers, to help customers create outstanding final products.

-

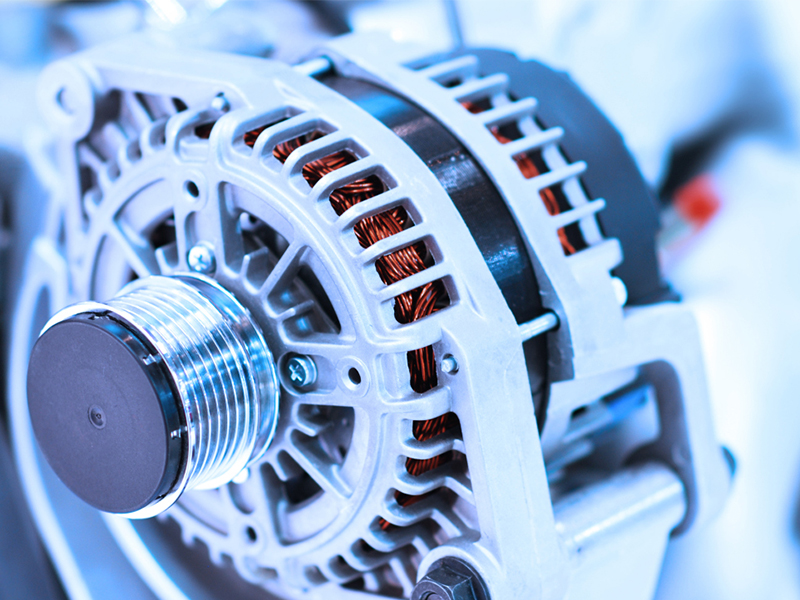

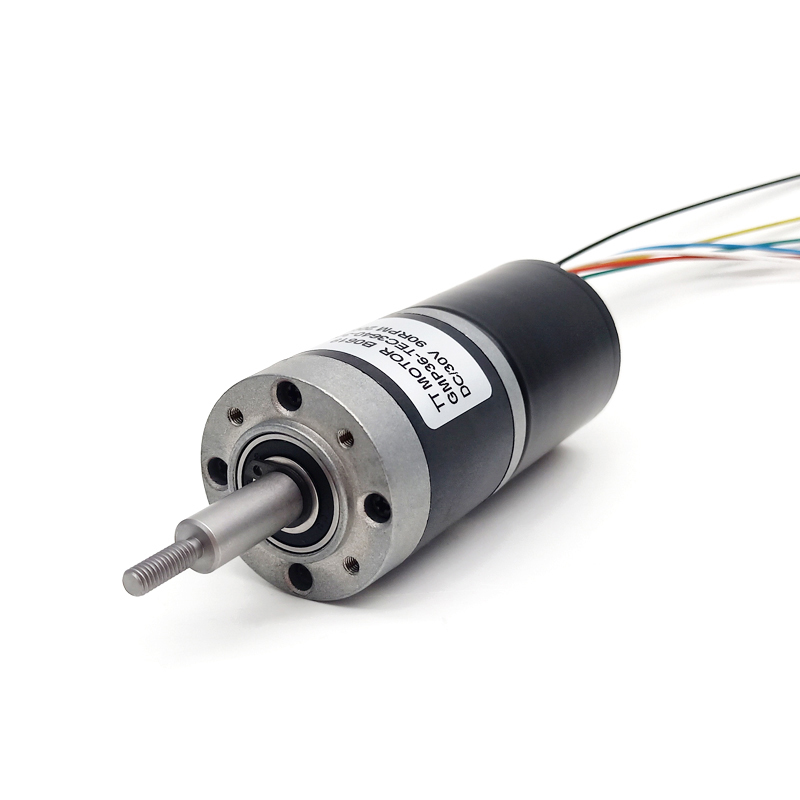

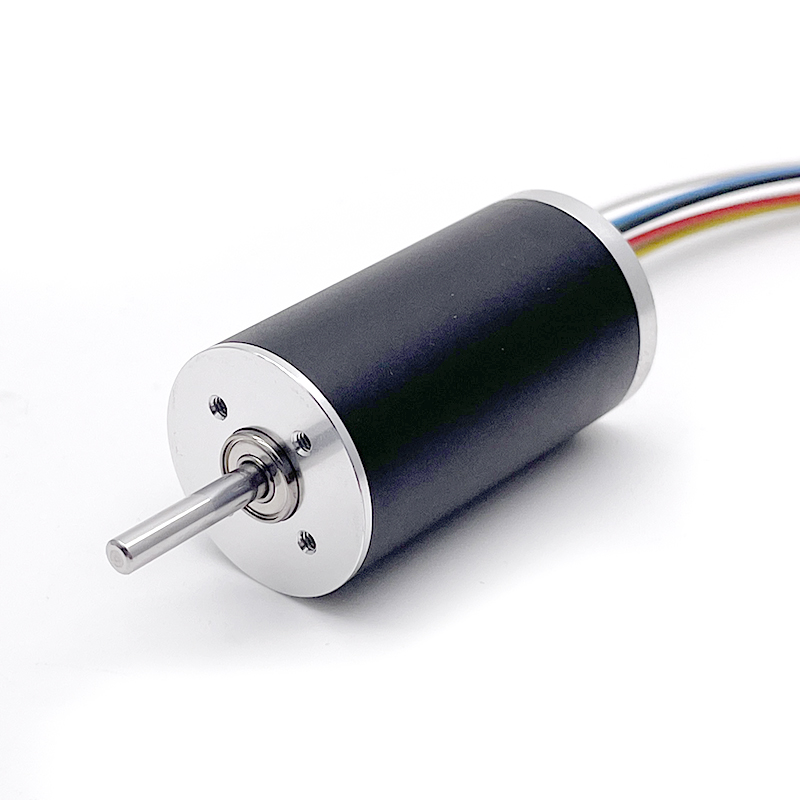

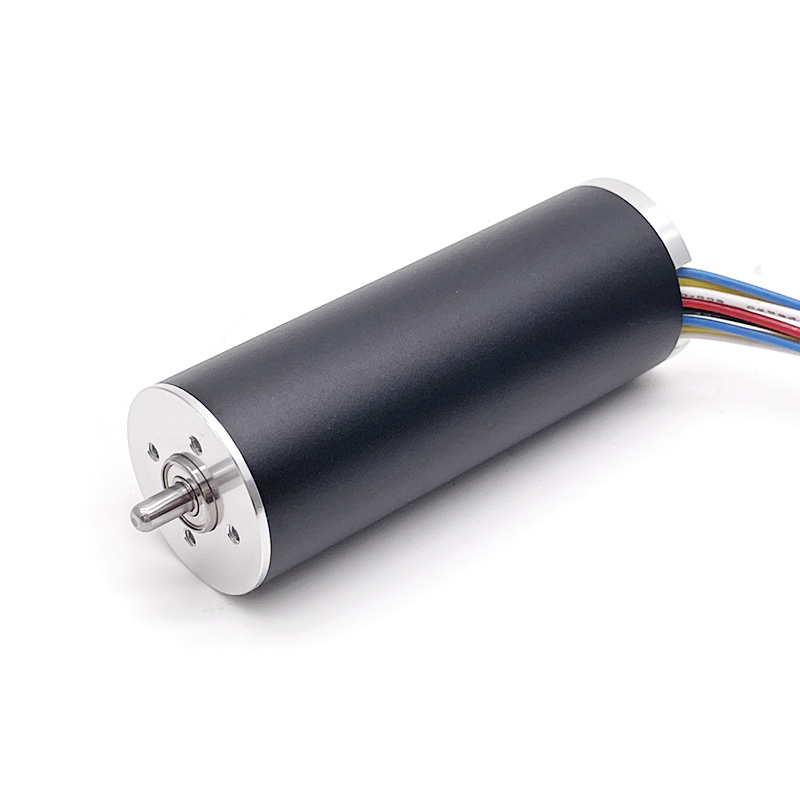

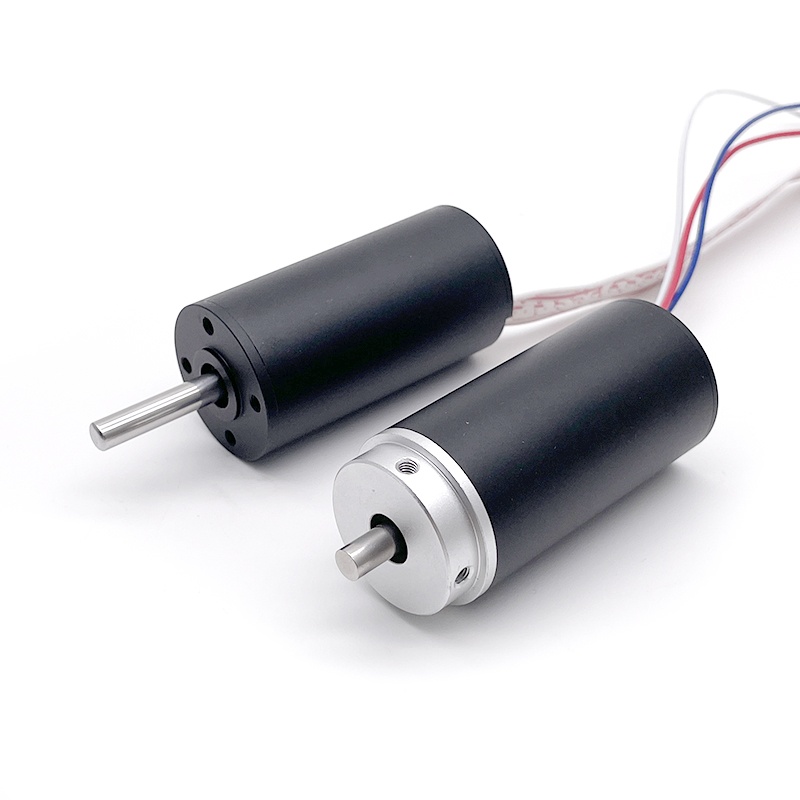

Brushed Motors and Brushless Motors

These are the traditional variety of DC motors which are used for basic applications where there is a very simple control system.

-

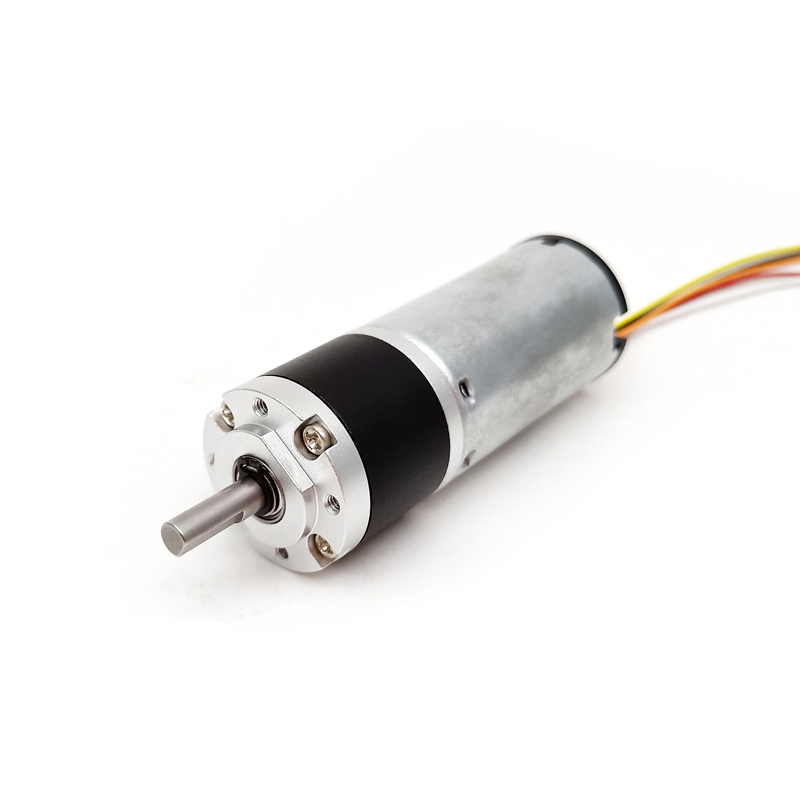

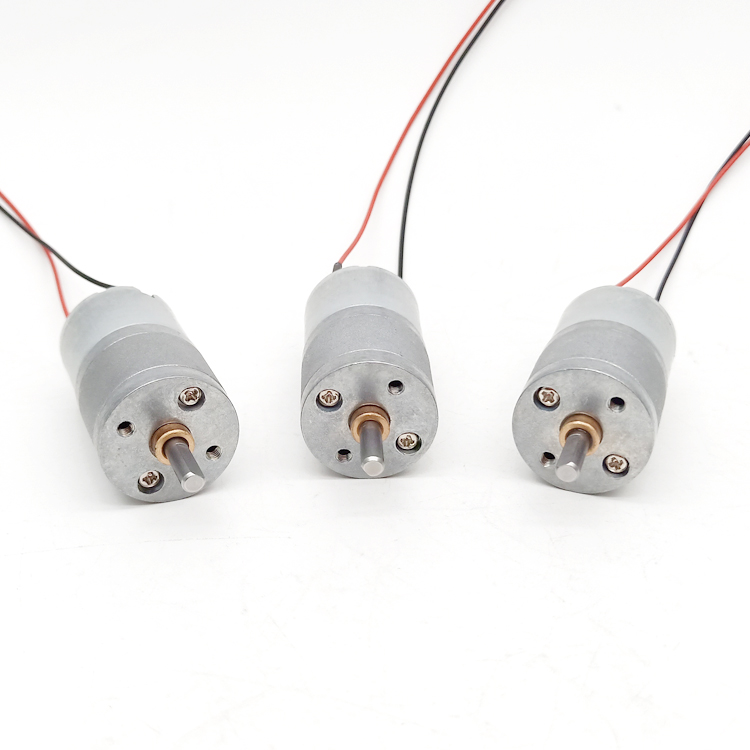

Micro Reduction Motor Features

Micro deceleration motor can also be designed according to the special requirements of customers, different shaft, speed ratio of the motor, not only let customers improve the efficiency of the work, but also save a lot of costs.

-

Motor FAQs

There are two kind brushes that we normally use in motor: the metal brush and carbon brush. We choose based on Speed, Current, and lifetime requirements.

-

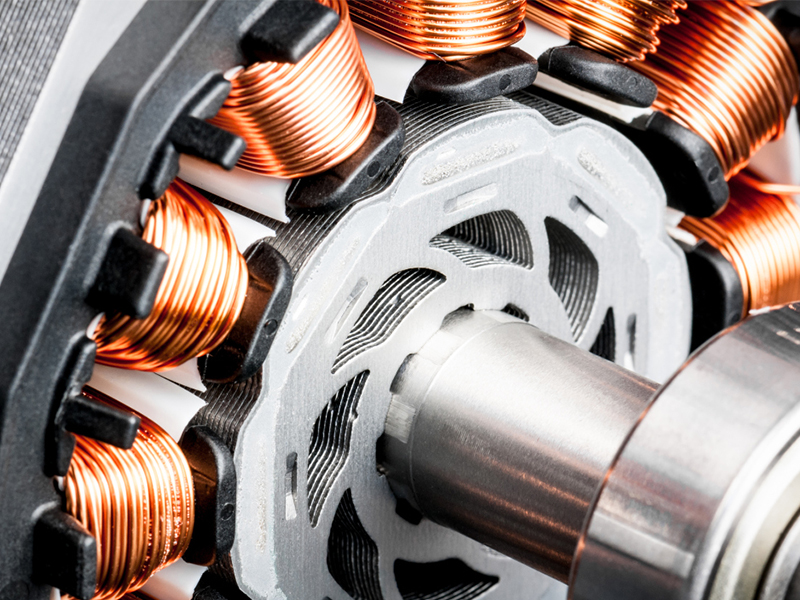

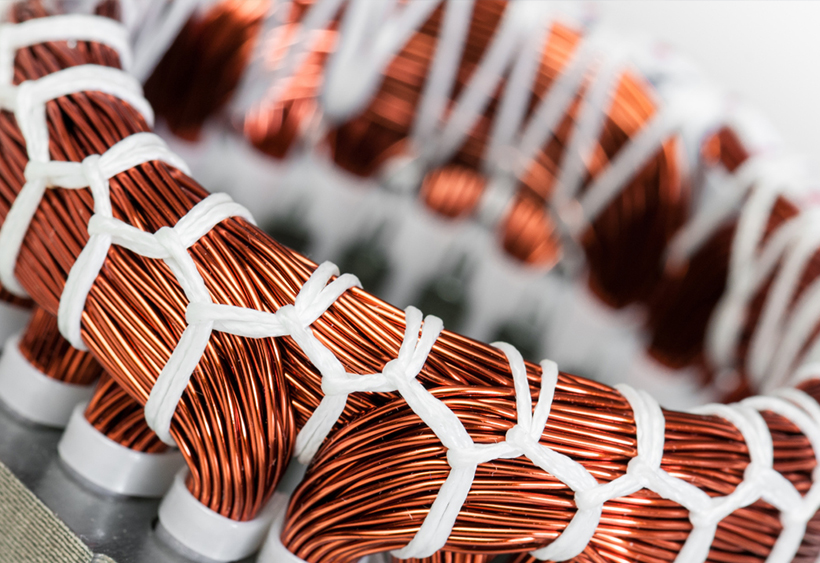

Slotted Brushless and Slotted Brushless Motors

The unique design of slotted brushless and slotted brushless motors has several important advantages:

OurAdvantages

-

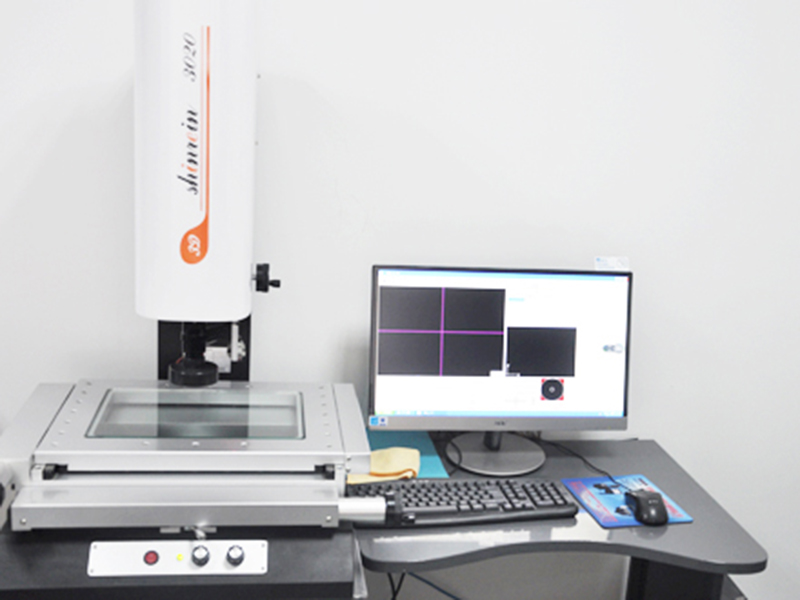

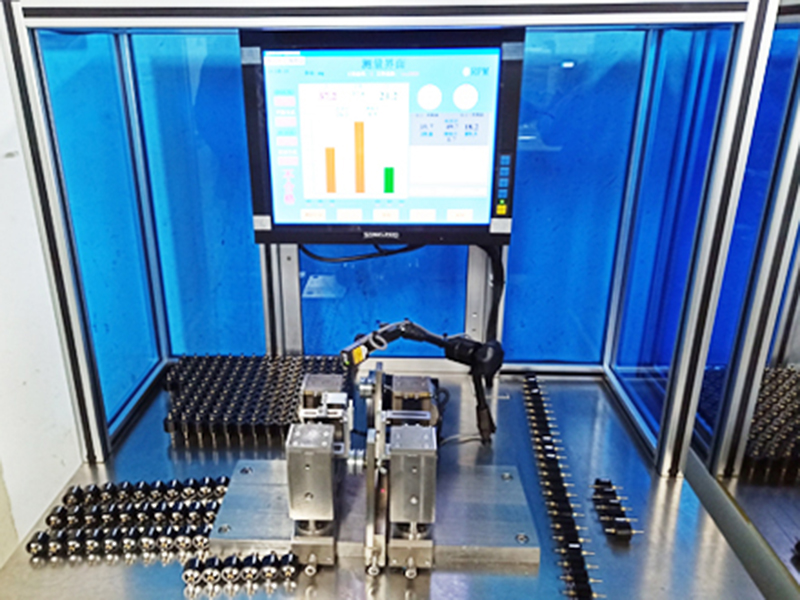

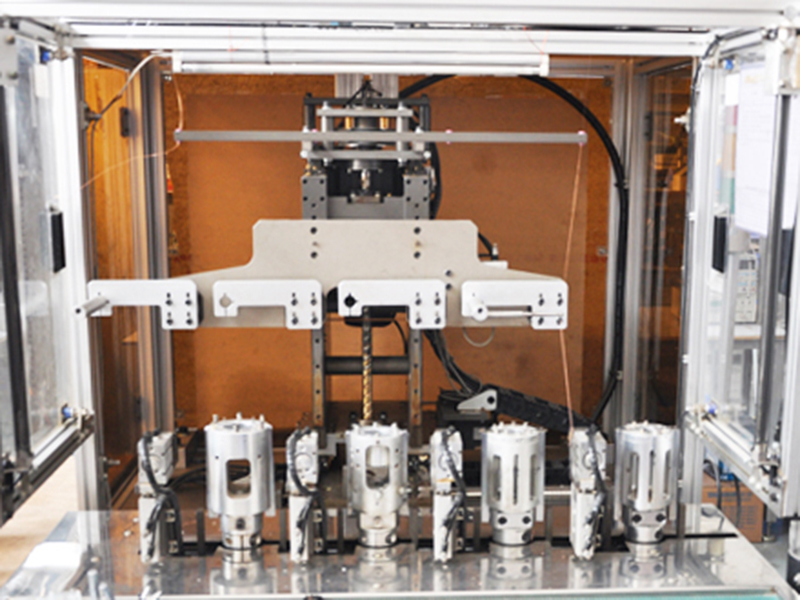

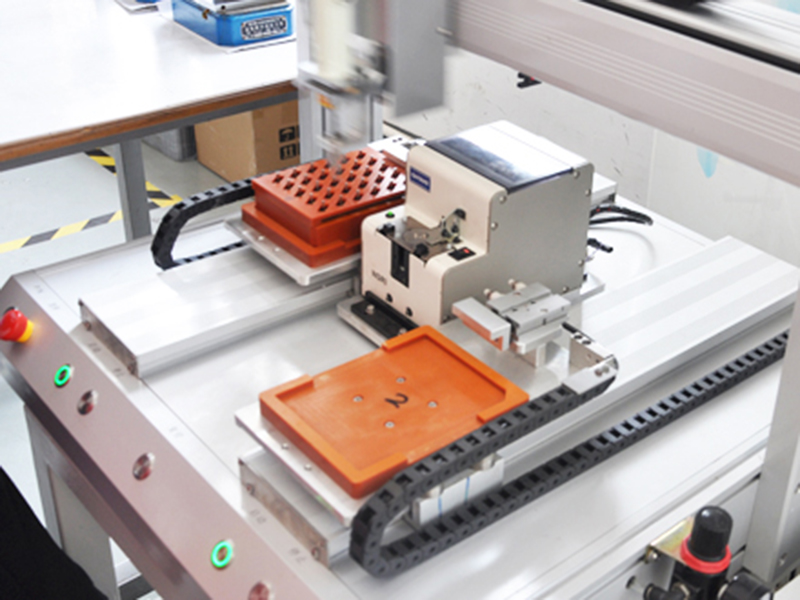

㎡ Customized service capability

Our factory covers an area of over 4500 square meters, with a total of more than 150 employees, two R&D centers, three technical departments,We have a wealth of customized service capabilities, including different shaft types, speed, torque, control mode, encoder types, etc., in order to fully meet the personalized needs of customers.

-

Years Design and manufacture

Focus on the field of motor for nearly 17 years, covering Φ10mm-Φ60mm diameter series of different sizes of motors, with rich experience in the research and development, design and production of micro gear motor, brushless motor, hollow cup motor, stepper motor.

-

+ High-tech enterprise

Major customers throughout Europe, America, Japan, Korea, Australia, etc.Motor exports more than 80 countries and regions,with an annual output value of more than 30 million dollars.

Ourstrength

hotproduct

newsinformation

-

Application of planetary gear motors

May-25-2024Planetary gear motors are widely used in various industries. Here are some specific examples: 1. Automated assembly lines: In automated assembly lines, planetary gear motors are often used to drive precisely positioned sliders, rotating parts, etc. Due to their high precision and high torque char...

-

Advantages of Planetary Gear Motors

May-21-2024The planetary gear motor is a transmission device that integrates the motor with the planetary gear reducer. Its advantages are mainly reflected in the following aspects: 1. High transmission efficiency: The planetary gear motor adopts the principle of planetary gear transmission and has high tra...

-

What are the special requirements for the application of DC motors in industrial robots?

Apr-29-2024The application of DC motors in industrial robots needs to meet some special requirements to ensure that the robot can perform tasks efficiently, accurately and reliably. These special requirements include: 1. High torque and low inertia: When industrial robots perform delicate operations, they ...